What is TC4 titanium alloy, TC4 titanium alloy performance/application explanation

What is the material of TC4 titanium alloy, alloy materials have a very important position today, from light industry to heavy industry, from low-end to high-end fields are inseparable from alloy materials. Titanium alloy is a very good alloy material, with a lot of characteristics, TC4 titanium alloy is one of them, today Shanghai titanium alloy manufacturers will take you to understand what TC4 titanium alloy is made of, let’s take a look.

TC4 titanium alloy is a medium-strength α-β type two-phase titanium alloy with the characteristics of low density, high specific strength, high heat resistance, etc., which is widely used in aerospace and chemical industries. TC4 titanium alloy is the world’s most widely used two-phase titanium alloy due to its excellent comprehensive properties, and has been widely used in the aviation and aerospace industry.

TC4 titanium alloy was developed and produced in China in the early 60s of the 20th century, and has been widely used in the manufacture of discs and blades of aero engine fans and compressors, as well as various load-bearing beams, frames, joints and fasteners in aircraft structures.

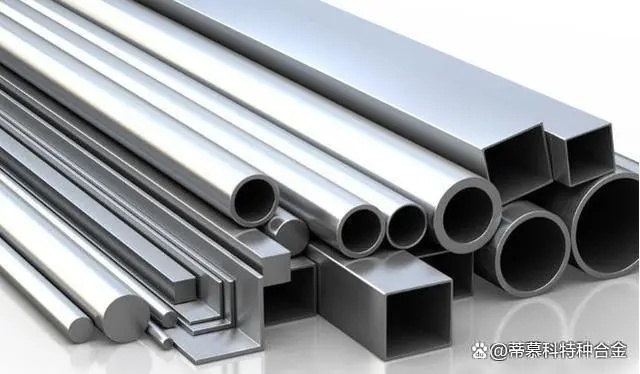

The main semi-finished products of TC4 titanium alloy are bars, forgings, thick plates, thin plates, profiles and wires. The alloy is mainly used in the annealed state, and can also be strengthened to a certain extent by solution aging treatment, but the quenching section is generally not more than 25mm.

The alloy has good process plasticity and superplasticity, and is suitable for various pressure molding. The alloy can also be welded and machined in a variety of ways.

The composition of titanium alloy TC4 material is Ti-6Al-4V, which belongs to (α+β) titanium alloy and has good comprehensive mechanical and mechanical properties.

The specific strength of titanium alloy is large. The strength of TC4 is sb=1.012GPa, the density g=4.51*103, and the specific strength sb/g=23.5, while the specific strength of alloy steel is less than 18.

Titanium alloys have low thermal conductivity. The thermal conductivity of titanium alloy is 1/5 of that of iron, 1/10 of aluminum, and the thermal conductivity of TC4 is l=7.955W/m·K.

Titanium alloys have a lower modulus of elasticity. The elastic modulus of TC4 is E=110GPa, which is about 1/2 of steel, so titanium alloy is easy to deform when machining.

TC4 (Ti-6Al-4V) and TA7 (Ti-5Al-2.5Sn) titanium alloys were modified by two injection schemes, and the test results showed that the microhardness of the titanium alloy was improved, the sliding friction coefficient was significantly reduced, and the wear resistance was effectively improved after ion implantation. In order to explore the modification mechanism, X-ray photoelectron spectroscopy (XPS) analysis was carried out on the injected and uninjected samples, and satisfactory results were obtained.

Founded in 2014, Shaaanxi Jiade Group Co., Ltd. specializes in the research and development, production, processing and sales of medium and high-end metal materials at home and abroad; The products cover aluminum alloy, stainless steel, alloy steel, special alloy, copper alloy and other metal materials. The company has established long-term material R&D and production cooperation with a number of material research institutes and wll-known material factories, and is good at the development of solutions and comprehensive applications of metal materials such as aerospace and semiconductor aluminum alloys and high-end special alloys; Now it has grown into a well-known distributor in the high-end metal materials industry. At present, the company’s high-end metal materials are widely used in aerospace, automotive, semiconductor, chemical equipment and other fields.

TC4 titanium alloy has the characteristics of low density, high specific strength, high heat resistance, etc., and has many applications in the aerospace and chemical industries, and is the world’s most used two-phase titanium alloy. “What are the advantages of nickel-based superalloys, and the explanation of nickel-based superalloy materials [alloy knowledge]“.