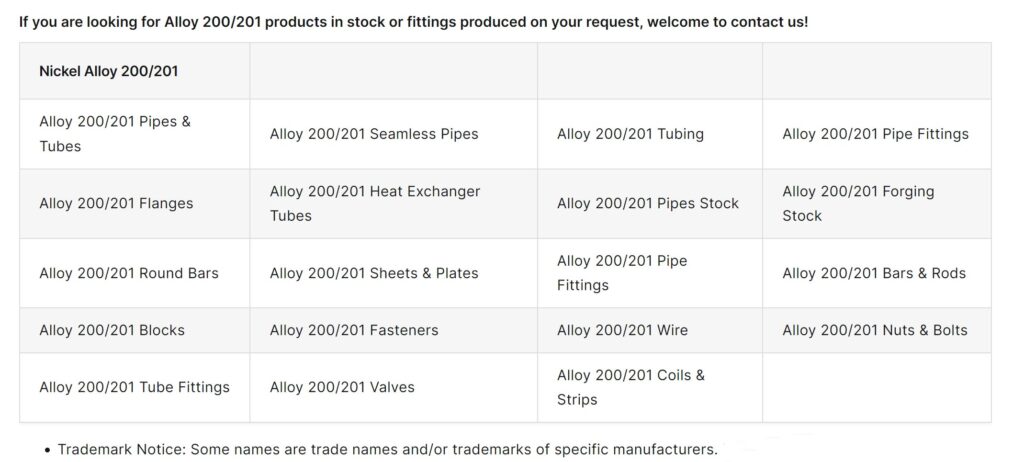

Nickel Alloy 200/201

Designated as UNS N02200 & W.Nr. 2.4060 & 2.4066, Nickel 200 or Ni 200 is 99.6% commercially pure wrought nickel. Nickel 200 has excellent resistance to many corrosive environments and good mechanical properties. Other useful features of Nickel 200 are its magnetic and magnetostrictive properties, low gas content, high thermal and electrical conductivities and low vapor pressure.

Designated as UNS N02201 or W.Nr. 2.4061 & 2.4068, Nickel 201 is has almost identical chemical composition as Nickel 200 except the lower-carbon content. Nickel 201 is typically applied in caustic evaporators, combustion boats, plater bars, as well as electronic components. Compared to Nickel 200, Nickel 201 has much lower base hardness and lower work-hardening rate hence is particularly suited for spinning and cold forming. According to ASME Boiler and Pressure Vessel Code Section VIII-Division 1, Nickel 201 is approved for construction of pressure vessels for service up to 1250°F. Its mechanical properties also vary depending on the manufacture process and heat treatment conditions.

Metline is a leading supplier of Nickel 200/Nickel 201 and other high-quality special metal alloys with decades of experience and extensive specifications.

Product Forms and Standards for Nickel 200/201

Equivalents of Nickel Alloy 200/201

Chemical Composition of Nickel Alloy 200/201

Mechanical & Physical Properties of Nickel Alloy 200/201

Nickel Alloy 200/201 Specifications

Specifications for Nickel 200 include the following:

- Nickel Alloy 200/201 Rod and bar: ASTM B 160/ ASME SB 160, DIN 17752, ISO 9723, VdTÜV 345.

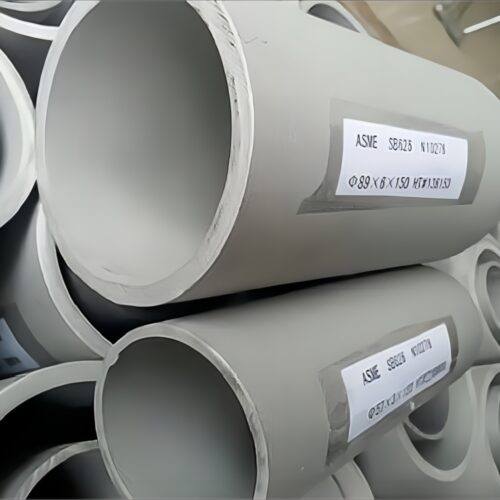

- Nickel Alloy 200/201 Pipe and Tube: ASTM B 161/ ASME SB161, B 163/ SB 163, B 725/ SB 725, B730/ SB 730, B 751/ SB 751, B775/ SB 775, B 829/ SB 829, DIN 17751, ISO 6207, BS 3074 (NA12), VdTÜV 345.

- Nickel Alloy 200/201 Plate, Sheet & Strip: ASTM B 162/ ASME SB 162, DIN 17750, ISO 6208, BS 3072-3073 (NA12), SAE AMS 5553, VdTÜV 345.

- Nickel Alloy 200/201 Fittings: ASTM B 366/ ASME SB 366

- Nickel Alloy 200/201 Forgings: ISO 9725, DIN 17754

- Nickel Alloy 200/201 Chemical Composition: DIN 17740

- Nickel Alloy 200/201 Wire: DIN 17753, ISO 9724