Stainless steel has good high temperature resistance. When the temperature exceeds 800[1], it begins to soften, and the allowable stress begins to decrease continuously. The maximum service temperature is 1200℃. Due to the high content of nickel (Ni) and chromium (Cr), 316 stainless steel bars have good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. After the content of carbon, the strength is improved due to its solid solution strengthening effect. The chemical composition characteristics of austenitic stainless steel are based on chromium and nickel, and elements such as molybdenum, tungsten, niobium and titanium are added. structure, thus high strength and creep strength at high temperature.

SPECIFICATION:

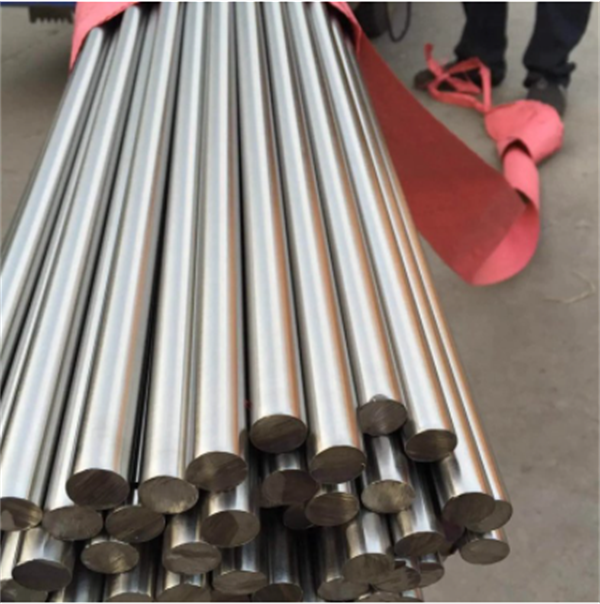

Products: Stainless steel round bar, Stainless steel square bar, Stainless steel plate bar

Type: Hot rolled and Cold Drawn

Diameter: ROUND:1/4”-16” Suqare: 15*15-300*300mm

Length: 1-12m or customized

Materials: 316

Standard:ASTM A276,A564,A582,A484

Surface treatment:Black ,peeled,bright,polished

Chemical Composition (wt%):

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 | Min | – | – | – | 0 | – | 16 | 2 | 10 | – |

| Max | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

Mechanical Properties:

| Grade | Tensile

Strength (MPa) min |

Yield

Strength Rp0.2% (MPa) min |

Elongation

(% in 50 mm) min |

Hardness | |

| Rockwell B (HRB) max | Brinell

(HB) max |

||||

| 316 | 515 | 205 | 40 | 95 | 217 |

Industry application:

316 stainless steel bars used for outdoor outdoor machines with high requirements for resistance to grain boundary corrosion in chemical, coal and petroleum industries, heat-resistant parts of building materials and parts with difficult heat treatment

1 . Petroleum waste gas combustion pipeline

2. Engine exhaust pipe

3. Boiler shell, heat exchanger, heating furnace parts

4. Muffler parts for diesel engines

5. Boiler pressure vessel

6. Chemical truck

7. Expansion joints

8. Spiral welded pipes for furnace pipes and dryers