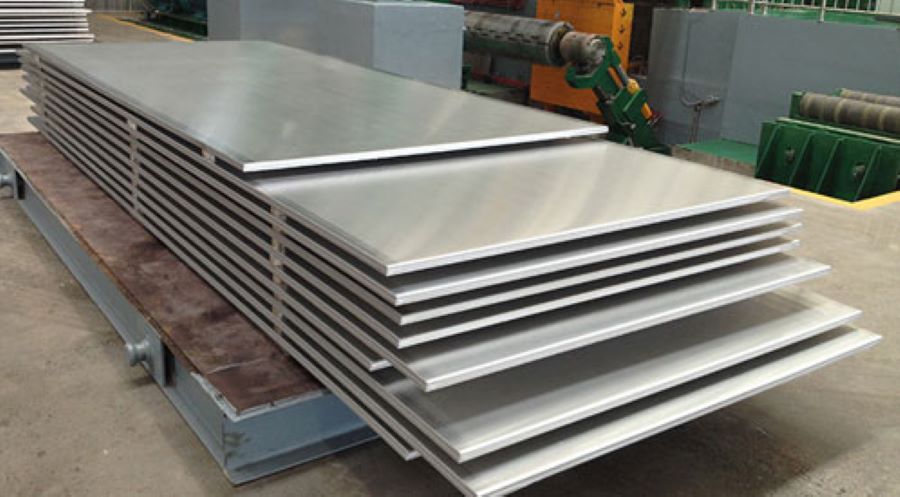

2205 Duplex Stainless Steel Sheet

2205 (UNS S32305/S31803) is a 22% Chromium, 3% Molybdenum, 5-6% Nickel, and Nitrogen alloyed duplex stainless steel with high general, localized, and stress corrosion resistance properties in addition to high strength and excellent impact toughness. Additionally, it provides pitting and crevice corrosion resistance superior to 316L or 317L austenitic stainless steels in almost all corrosive media. It also has high corrosion and erosion fatigue properties as well as lower thermal expansion and higher thermal conductivity than austenitic.

2205 duplex stainless steel sheet Specification

Width: 500-2500mm

Length: 1000-12000mm

Thickness: Cold Rolled: 0.3-3mm, Hot Rolled: 3-120mm

Standard: ASTM A240, ASTM A480, EN10088-2, etc.

Surface Finish: No.1 No.4, 2B, 2D, BA, HL, No.8, Mirror finish, and more.

2205 Duplex Stainless Steel Chemical Composition (by mass%):

| Grade | UNS | C | mn | Si | P | S | Cr | Mo | Ni | N | ||

| 2205 | S32205 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 22.0-23.0 | 3.0- 3.5 |

4.5-6.5 | 0.14-0.20 _ |

||

2205 stainless steel Mechanical properties:

| Grade | UNS No. | Tensile Strength (MPa) min |

Yield Strength (MPa) min |

Elongation (% in 50mm) min |

Hardness max | |

| Rockwell (HRB) | Brinell (HB) | |||||

| 2205 | S32205 | 620 | 450 | 25 | 31HRC | 293 |

Corrosion Resistance

General Corrosion

Because of its high chromium (22%), molybdenum (3%), and nitrogen (0.18%) contents, the corrosion resistance properties of 2205 duplex stainless steel plate are superior to that of 316L or 317L in most environments.

Localized Corrosion Resistance

The chromium, molybdenum, and nitrogen in 2205 duplex stainless steel plate also provide excellent resistance to pitting and crevice corrosion even in very oxidizing and acidic solutions.

Isocorrosion Curves 4 mpy (0.1 mm/yr), in a sulfuric acid solution containing 2000 ppm

Chloride Pitting Resistance

The pitting resistance of austenitic stainless steel can be related directly to alloy composition, where chromium, molybdenum, and nitrogen are a weight %. The Pitting Resistance Equivalent Number (PREN) uses the following formula to measure an alloy’s relative pitting resistance – the higher the number, the better the pitting resistance.

Applications

- Pressure vessels, tanks, piping, and heat exchangers in the chemical processing industry

- Piping, tubing, and heat exchangers for the handling of gas and oil

- Effluent scrubbing systems

- Pulp and paper industry digesters, bleaching equipment, and stock-handling systems

- Rotors, fans, shafts, and press rolls requiring combined strength and corrosion resistance

- Cargo tanks for ships and trucks

- Food processing equipment

- Biofuels plants