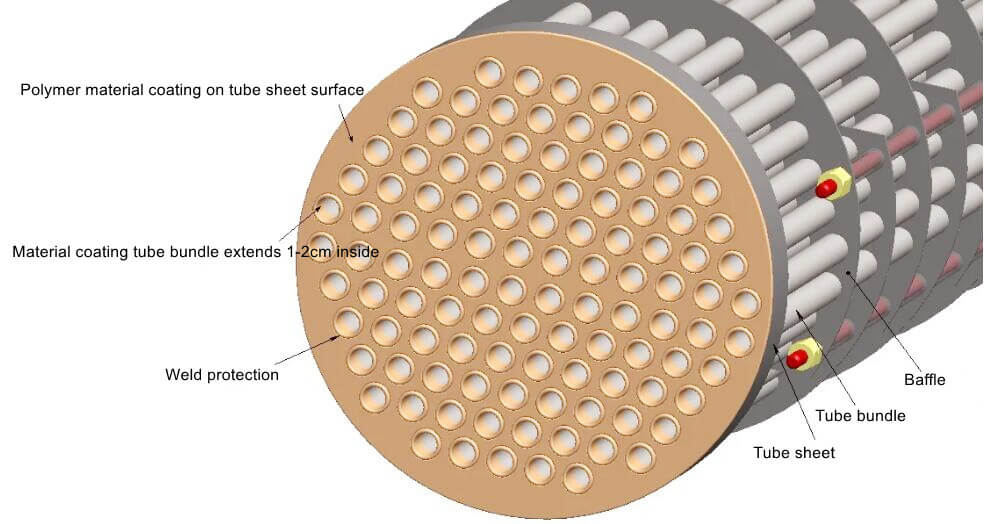

Heat exchanger is the heat transfer from the hot fluid part to the cold fluid, so that the fluid temperature reaches the process requirements indicators of heat exchange equipment, can also be called heat exchange equipment. Tube heat exchanger is mainly composed of tube bundle, shell, folded plate (baffle), head, tube sheet. The shell is mostly cylindrical, equipped with internal tube bundle, tube bundle ends by welding or expansion of the way fixed in the tube sheet, in the work of hot and cold two kinds of fluid flow in the tube bundle to become a tube process; a flow in the shell called shell process. Once the tube plate corrosion leakage, will cause the emergence of media cascade situation, seriously affecting product quality and smooth operation of equipment, if the media for special media, then seriously will cause safety accidents.

Heat exchanger material is generally based on carbon steel, stainless steel and copper, tube plate and tube connection is generally welded, expansion and expansion welding combination of the way. Tube plate and tube using expansion welding combined way, due to the shape of the weld exists in varying degrees of defects, such as depressions, porosity, slag, etc., the distribution of weld stress is also uneven, the weld welding led to changes in its own material, when encountering corrosive media, the weld position is very easy to corrosion, rust caused by leakage at the weld position. Secondly, the chloride ions in the water and electrochemical corrosion problems are also prone to cause corrosion of the weld position resulting in leakage, affecting the service life of the heat exchanger, causing losses to the production enterprises. For a long time this problem has not been properly solved, becoming a problem in the industry.

Research shows that industrial water, whether freshwater or seawater, there will be a variety of ions and dissolved oxygen, which changes in the concentration of chloride ions and oxygen, the corrosion of metal shape plays an important role. In addition, the complexity of the metal structure will also affect the corrosion shape. Therefore, the corrosion of the tube sheet and the tube weld is dominated by pore corrosion and crevice corrosion. From the outside, the surface of the tube sheet will have many corrosion products and accumulation of sediment, the distribution of craters of varying sizes. When seawater is used as the medium, it will also produce galvanic corrosion. Chemical corrosion is the corrosion of the medium, heat exchanger plate contact with a variety of chemical media, it will be subject to the corrosion of chemical media.

In addition, the heat exchanger plate will also produce a certain amount of bimetallic corrosion between the heat exchanger tube. Some of the plate is also in the long-term corrosion of the media erosion. Especially fixed plate heat exchanger, there is a temperature stress, the tube and heat exchanger tube joint is very easy to leak, resulting in heat exchanger failure.

Therefore, the corrosion and protection of the tube sheet becomes particularly important, and now, the field repair of Solay carbon nanopolymer material specifically for the corrosion and protection of the tube sheet provides a new excellent industrial maintenance process.

The development of heat exchanger tube sheet corrosion protection process

For corrosive media caused by the heat exchanger tube sheet and weld position corrosion problems, the traditional way is to mark the leakage point after playing pressure to patch welding way. But after welding, the release of welding stress and welding position material changes, are prone to cause secondary corrosion leakage of the tube sheet. In addition to improve the corrosion resistance of the body by upgrading the material grade of the equipment itself to extend the service life, but it will add a lot of cost to the enterprise.

Polymer composite material protection process

The use of polymer materials to implement surface organic coating anti-corrosion is currently one of the effective anti-corrosion measures. Polymer composite material is a high-tech discipline developed on the basis of polymer chemistry, organic chemistry, colloid chemistry and material mechanics, etc. It uses polymer penetration to form the force between molecules, so that it forms van der Waals force and hydrogen bonding link with the repaired parts, thus ensuring its bonding performance with the repaired and protected parts.

Polymer composites can form a cured form of protective coating on the protected substrate and play a shielding role, so that the base metal and corrosive media are separated from each other to avoid corrosion and rusting; the coating has anti-penetration properties, stability to corrosive media, strong adhesion, compatible mechanical properties, etc., which ensures the application effect of the protective coating and the operating cycle of the equipment. Compared with the traditional welding repair, anti-corrosion coating protection technology has the characteristics of easy construction, low cost, high safety and good repair effect. In this regard, polymer composite technology has good application experience and technical products.

Analysis of heat exchanger problems

Heat exchanger is the use of circulating cooling water temperature to control the shell process media temperature, in the operation process when the shell process media temperature is high when relying on the heat exchanger to shell process media for cooling, cooling circulating water in the tube bundle flow, shell process media in the shell outside the tube bundle flow, through the exchange of heat between the two, and then the shell process media to achieve the purpose of the process temperature requirements. Due to the use of the process, the circulation of cooling water in the tube bundle circulation, it is very easy because of the impurities in the circulating water wash caused by the tube sheet on the tube bundle welding port corrosion leakage; In addition, in operation, the water conveyed in the tube bundle is an electrolyte, so the heat exchanger tube sheet corrosion causes there is a part with electrochemical properties, water impurities in the corrosion of the greatest impact is the dissolved oxygen in the water, the PH value of the water will obviously affect Heat exchanger tube sheet corrosion rate.

Heat exchanger tube sheet corrosion solutions

To a large coal chemical industry heat exchanger corrosion protection, for example, the diameter of 3 meters, the shell process pressure up to 17 kg, the tube process temperature up to 150 ℃. The harsh working environment has put forward higher requirements on our technology and products. The surface of the tube sheet is first sandblasted to remove surface rust and other impurities, and after the surface treatment meets the requirements, polymer composite materials are used to protect the surface of the tube sheet as a whole against corrosion.

Heat exchanger tube sheet anti-corrosion steps

- Preparation work: heat exchanger disassembly to ensure construction safety and leave operable space.

- Pressure leak testing: test the leak point and mark the location in accordance with the rated pressure, patch welding treatment.

- Chamfering treatment: the use of power tools and other parts of the corners and edges of the pipe mouth chamfering treatment (see below), in order to increase the material adhesion area, increase the anti-corrosion coating and bonding effect.

- Surface treatment: surface sandblasting treatment to clean the surface adhesion, reveal the original color of the metal and ensure that the surface is dry.

- Clean surface: use compressed air (no water and no impurities) to blow the dust dry, immediately spraying Fushi Blue pretreatment agent to prevent rust and corrosion.

- Apply material: mix EE-101 material according to the ratio and apply the material evenly to the repair part (the cratered part of the board surface with serious corrosion can be repaired by using 2211F material for leveling).

- Curing: waiting for the material to cure.

- Thickness and EDM testing: use EDM and thickness tester to ensure that the material completely covers the surface of the pipe plate.

- Pressure test: pressure test the repaired heat exchanger to ensure that there are no leaks.

- Equipment installation: After the material has reached the curing requirements, it can be installed and used. During the installation process, avoid impact and knocking on the repaired parts.

Repair diagram

Diagram of repair of heat exchanger tube sheet

Matters needing attention

- Surface treatment to remove foreign matter such as grease and rust.

- Mixing the materials strictly according to the proportion.

- Master the material curing time to ensure that the material is completely cured and has met the conditions of equipment use.

- The above plan can be adjusted according to the actual situation on site.