HastelloyC2000 steel

Hastelloy steel is a difficult metal material, the extension dislocation is very wide, in the high temperature thermal deformation, the dislocation caused by the deformation of the interleaved slip and the climbing of the blade dislocation are more difficult, the dislocation is freed from the node and dislocation network, and the heterogeneous dislocation cancels each other, so that the dislocation density in the high-neck steel plate increases, the energy storage of material deformation becomes larger, and the softening effect produced by deformation is mainly dynamic recrystallization. At the same time, with the increase of deformation temperature, the thermal vibration energy generated during the deformation of WN steel plate continues to increase, and the softening effect on the material continues to become stronger, therefore, under the same strain rate condition, the rheological stress increases with the deformation temperature, and the rheological stress peak, with the increase of the deformation temperature, moves in the direction of small strain variable.

Hastelloy alloy steel plate belongs to difficult to forge metal material, the extension dislocation is very wide, in the high temperature thermal deformation, the dislocation caused by the deformation of the interleaved slip and the climbing of the edge dislocation are more difficult, the dislocation is freed from the junction and dislocation network, and the dislocation cancels each other, so that the dislocation density in the high-neck steel plate increases, the energy storage of material deformation becomes larger, and the softening effect caused by deformation is mainly dynamic recrystallization. At the same time, with the increase of deformation temperature, the thermal vibration energy generated during the deformation of WN steel plate continues to increase, and the softening effect on the material continues to become stronger, therefore, under the same strain rate condition, the rheological stress increases with the deformation temperature, and the rheological stress peak, with the increase of the deformation temperature, moves in the direction of small strain variable.

1. Pure nickel: N5, N02201, Ni201, 2.4068, Ni99.0LC, N6, N7, N02200, Ni200, 2.4066, Ni99.0.

2, Monel (Monel): N04400, N05500, Monel K500, national standard: 67Ni30Cu.

3. Inkoloy alloy: N08800, Incoloy800, N08810, Incoloy800H, N08811, Incoloy800HT, N08825, Incoloy825, N08020, N08028, N08031, Alloy31, Alloy28 alloy, Alloy20 alloy.

4. Inconel alloy: N07750, Inconel-X750 alloy, N07718, Inconel718 alloy, N06600, Inconel 600, N06601, Inconel601 alloy, N06690, Inconel690 alloy, Inconel600 alloy, N06600, N06625, Inconel625 alloy, ZRJWXTG。

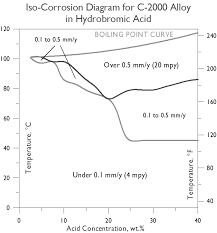

5, Hastelloy alloy: Hastelloy B-2, Hastelloy B-3, Hastelloy C-276, Hastelloy C-22, Hastelloy C-2000, Hastelloy G-30.

The commonly used alloy steel plate is made of stainless steel, which has high permeability and starting permeability and low coercivity, and is an important material in the electronics industry. The main elements of the alloy are chromium, aluminum, copper, this alloy has high resistivity, low resistivity temperature coefficient and good corrosion resistance, used to make resistors, nickel-based electrothermal alloy is a nickel alloy containing 20% chromium, with good corrosion resistance, can be used for a long time at 1000~1100 °C temperature. Nickel-based alloy steel plate is a material containing 50% nickel, its recovery temperature is 70 °C, good shape memory, a small amount of change in the proportion of nickel-titanium composition, can be used in the temperature range above 1200 °C, mostly used in the manufacture of incinerators, hydrogenation furnaces and other uses.

Low-pressure steel plate is vulnerable to sulfur, when it is in contact with sulfur-containing substances, the temperature exceeds the critical value of 300 degrees Celsius, hot sulfur will penetrate into the grain boundary into nickel sulfide, in oil, dust, paint, marking ink, adhesive tape, fingerprints, sweat, footprints, and other substances will have sulfur presence, welding also wear clean work clothes, clean gloves, can not directly touch the material with hands, materials can not contact with iron, the ground, must not be marked with markers, When welding steel plates, the welding mouth should be scrubbed with binger or alcohol and the range of 50mm on both sides to remove moisture, oil, etc.