Introduction

321 stainless steel grade is a really common grade preferred for heat-resistant applications. This grade is written as 1.4541 or X6CrNiTi18-10 according to EN norm and it is written as UNS S32100 according to UNS norm. 1.4541 stainless steel is similar to the mix of 304 and 316Ti grades and we can think of 321 grade as the mixture of these two different grades. This grade has good corrosion resistance and at temperatures like 600-700 degrees, this grade has still good heat and corrosion resistance. 321 stainless is widely used in Germany and Russia. If this grade is not enough because of its heat resistance, then 310 / 310s grades can be chosen for higher temperatures. The ingredient of 321 grade is similar to 304 stainless steel grade so 321 grade can be considered as the titanium added version of 304 grade.

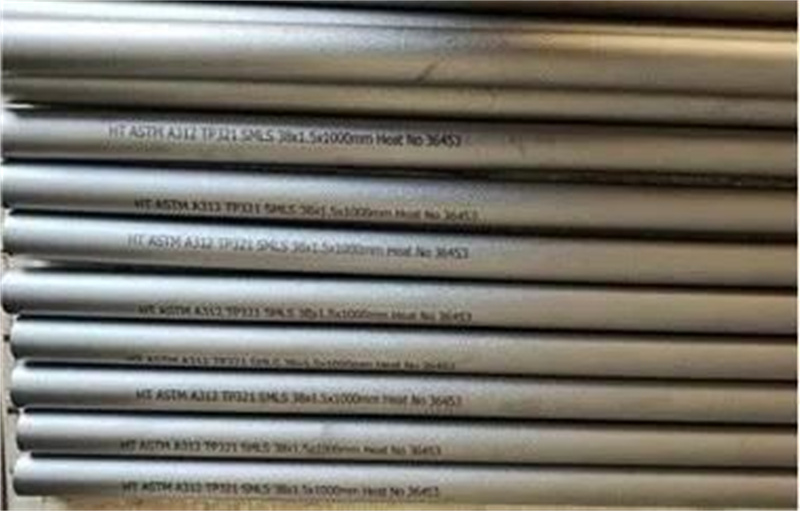

Production Specification

Standard:ASTM A409, A312,JIS G3459, JIS G3463

OD: 10-1067mm

WT: 1-150mm

Length:1000-13000mm

Surface treatment: Mill finished, Polished.

321 Stainless Steel Pipe Chemical Composition:

| Element | 321 | 321H |

|---|---|---|

| Chromium | 17.00 min.-19.00 max. | 17.00 min.-19.00 max. |

| Nickel | 9.00 min.-12.00 max. | 9.00 min.-12.00 max. |

| Carbon | 0.08 | 0.04 min.-0.14 max. |

| Manganese | 2.00 | 2.00 |

| Phosphorus | 0.045 | 0.045 |

| Sulfur | 0.03 | 0.03 |

| Silicon | 0.75 | 0.75 |

| Titanium | 5 x (C + N) min.-0.70 max. | 4 x (C + N) min.-0.70 max. |

| Nitrogen | 0.10 | 0.10 |

| Iron | Balance | Balance |

321 Stainless Steel Pipe Mechanical Properties:

| Yield Strength 0.2% Offset |

Ultimate Tensile Strength |

Elongation in 2 in. |

Hardness | ||

|---|---|---|---|---|---|

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 30,000 | 205 | 75,000 | 515 | 40 | 217 Brinell |

Applications

Aerospace – piston engine manifolds

Chemical Processing

Expansion Joints

Food Processing – Equipment and storage

Petroleum Refining – polythionic acid service

Waste Treatment – thermal oxidizersPharmaceutical Production