INFORMATION

Inconel 625 alloy technical parameters

| Inconel 625(UNS N06625) | |||||||||

| Summry | Nickel-chromium-molybdenum alloy, which is added with niobium element, basically hardens the alloy together with aluminum, thus showing high strength performance without heat treatment and strengthening. The alloy is resistant to various harsh corrosive environments, especially pitting and crevice corrosion. For chemical, aviation and marine engineering, pollution control equipment and nuclear reactors | ||||||||

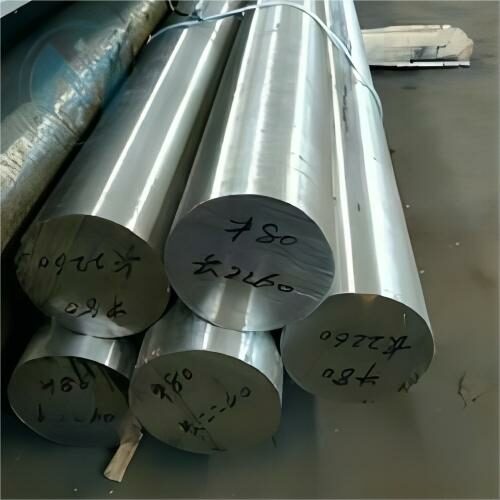

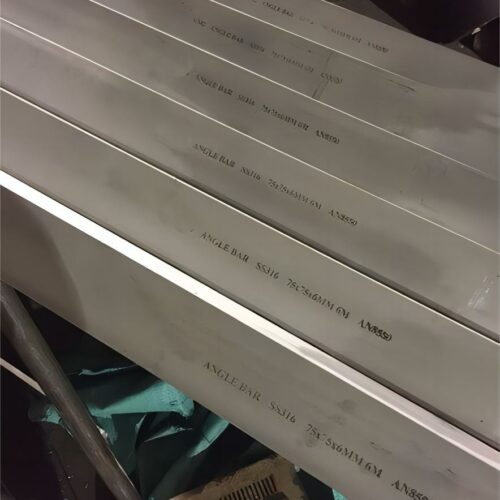

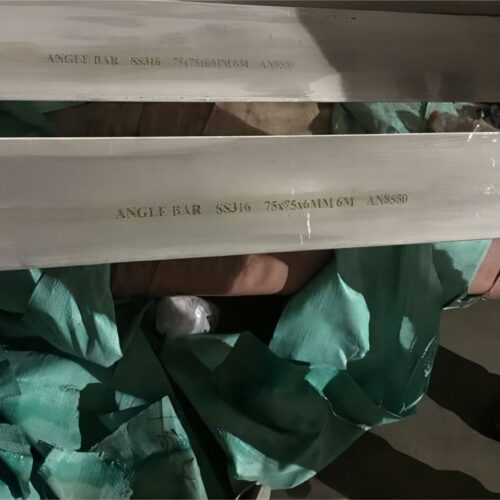

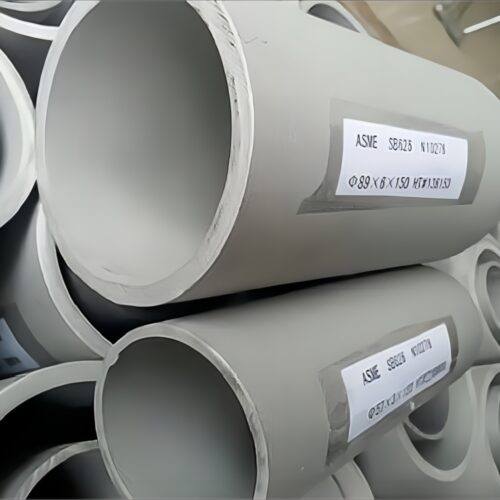

| Product | Pipe, plate, strip, round rods, flat rods, forgings, wire, special profiles, extrusions | ||||||||

| Chemical Composition | Min. | Max. | Min. | Max. | Min. | Max. | |||

| Ni | 58.0 | Cu | C | 0.1 | |||||

| Cr | 20.0 | 23.0 | Co | 1.0 | Si | 0.5 | |||

| Fe | 5.0 | Al | 0.4 | P | 0.015 | ||||

| Mo | 8.0 | 10 | Ti | 0.4 | S | 0.015 | |||

| Nb | 3.15 | 4.15 | Mn | 0.5 | N | ||||

| Physical Constant | Density, g / cm ³ 8.44 | ||||||||

| Melting range,℃ 1290-1350 | |||||||||

Metallographic structure

Inconel 625 is a basic strengthened face-centered cubic crystal lattice alloy of solid solution type.

Characters

Inconel 625 due to the low carbon content and stable heat treatment, it still only shows a very small sensitization trend after 50 hours in 650-900℃.

Low-carbon lnconel 625 in the softening of the annealing state (Inconel 625 Gr.1) Application related to wet corrosion and approved by TUV for manufacture of pressure vessels within-196-450℃.In high temperature applications above about 600℃, it must have high strength and creep fracture resistance, and high carbon.Inconel 625 in the condition of solution can meet customers more applications in annealing state .

1.Excellent spot corrosion resistance, gap corrosion and intercrystalline corrosion performance;

- Almost completely free from stress corrosion rupture caused by chloride ion;

- Good corrosion resistance to inorganic acids, such as nitric acid, phosphoric acid, sulfuric acid and hydrochloric acid;

4.Good alkali resistance and organic acid corrosion performance;

- Good mechanical properties.

Corrosion resistance

Alloy 625 shows excellent corrosion resistance in many media. In the chloride medium has excellent spot corrosion resistance, crevice corrosion, such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid, etc., in the oxidation and reduction environment also has the performance of material corrosion. With air to manage the material to, in the sea.There is almost no corrosion in the gas environment, which has high corrosion resistance to seawater and salt solution.It has high corrosion resistance to seawater and salt solution. The same is true at high temperature. There is no sensitivity during welding. It has carbonization and oxidation resistance, and is resistant to chlorine-containing gas corrosion